Digital fabrication and automation are assuming greater centrality in architecture by redefining design and production processes. However, current fabrication tools fall short of addressing custom high-skill tasks and handling materials with a high degree of uncertainty. As manual work cannot yet be fully automated, there is a continued demand for high-skilled workers to perform custom building tasks. In this context, decoding manual techniques is essential for transferring building craft to robotic fabrication. Craft is defined by an intimate relationship between the craftsman and the material at hand. The advantage of craftsmen lies in their ability to overcome conditions arising from the inherent uncertainty of raw building materials. This ability is achieved by the craftsman’s real-time decision-making process, based on visual and haptic feedback enabled by the human nervous system.

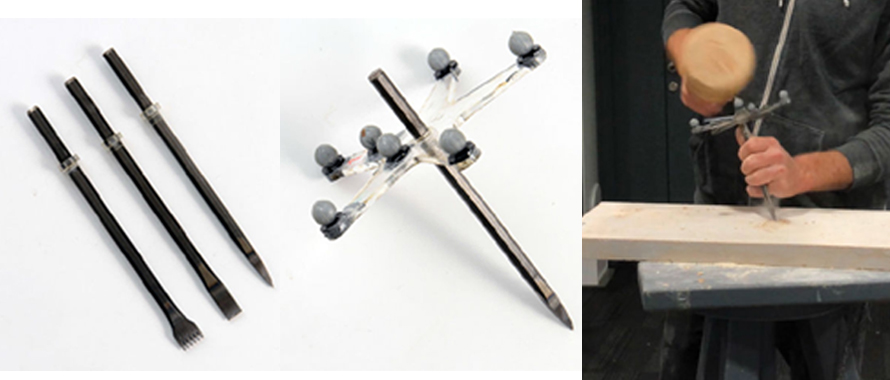

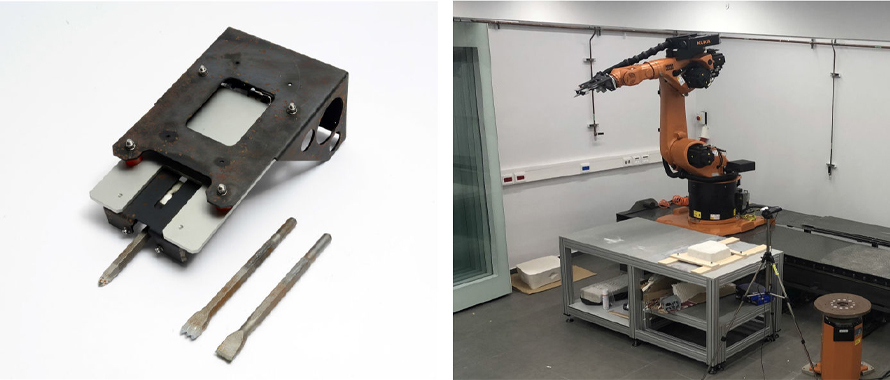

This research offers a method for documenting human decision-making in architectural crafts and augmenting manual gestures’ sensitivity as a basis for robotic construction. Similar to human arms, robotic arms with six-degrees-of-freedom can reach arbitrary poses (position and orientation) in three-dimensional space. Moreover, robotic arms can be attached with custom tools (end-effectors), integrate with sensors, perform custom precision tasks, and enhance manual processes. In this context, the research hypothesis is that incorporating robotic arms in architecture can help preserve, augment, and enhance traditional building craft – for instance, stonework. Stonework is a longstanding construction tradition, encompassing a multitude of manual tools and techniques for transforming raw material into building elements. Advancements in robotic fabrication allow revisiting these practices using digital tools. However, stonework is complex to automate due to unpredictable material behavior.

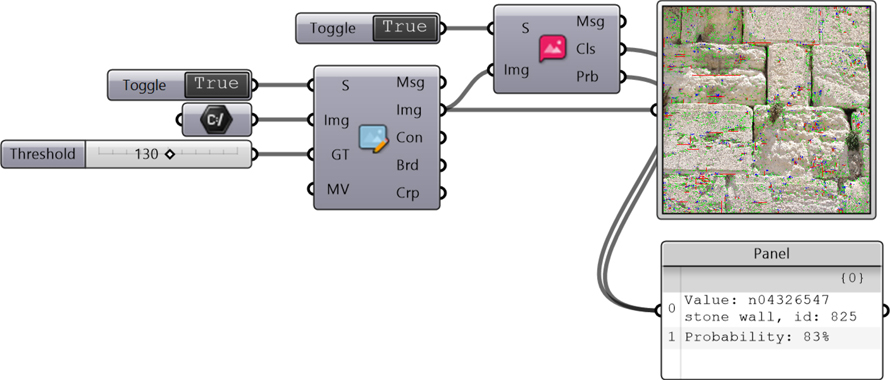

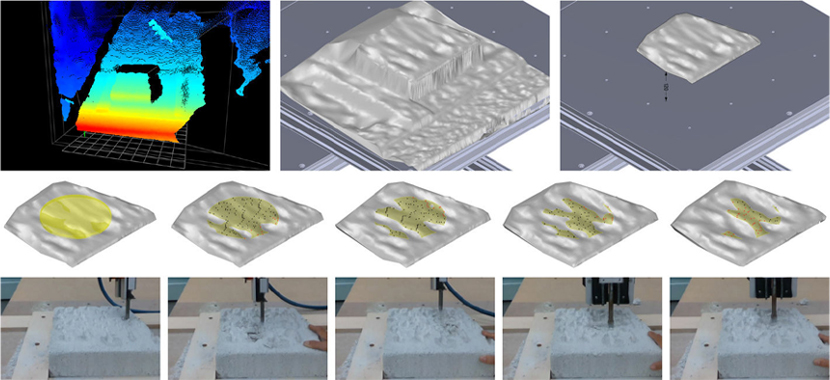

To this end, this research focused on developing custom robotic tools, including a multi-tool carving end-effector, a sensor toolkit, and supporting craft-oriented middleware. These tools address the need for sensor-based feedback in robotic fabrication involving uncertain materials, non-structured environments, or post-production surfaces. The custom middleware enables overcoming these fabrication challenges by allowing the robot to react to different material scenarios in real-time without a predetermined program.

The middleware and its components are presented, followed by experiments demonstrating its capacity. The dissertation thus expands existing research on digital stonework, human-robot craft transfer, and robotic fabrication. It puts forth a computational strategy for documenting, analyzing, and simulating manual stonework and its transfer to adaptive robotic carving protocols for surface finishing and detailing. The experiments’ results indicate the potential of automating custom stonework for tasks currently limited to manual carving. Additionally, the research outcomes help preserve local crafts, augment them, introduce sensitivity to existing robotic tools, and perform digital architectural fabrication with previously overlooked materials – thus increasing future construction resilience.